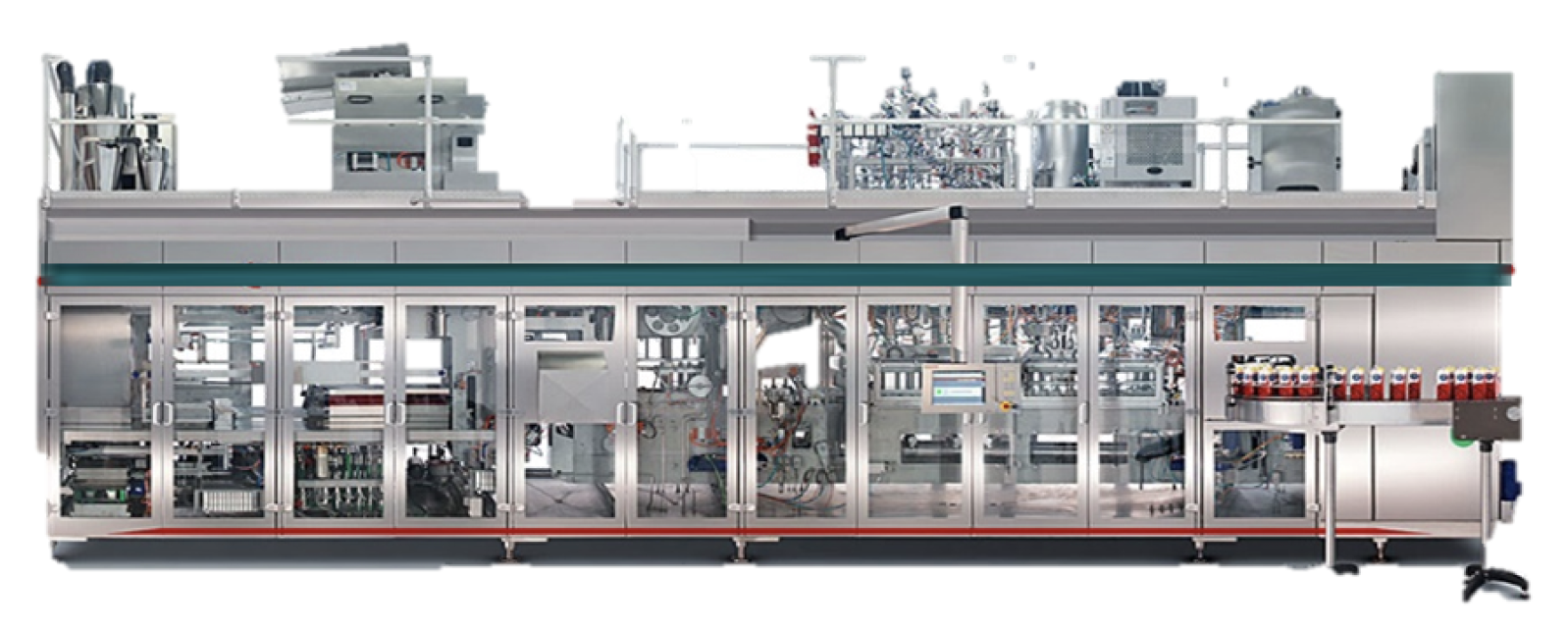

Filling machine for ambient cartons

Broaden your horizon of aseptically filled products and embrace the possibilities of new markets. Our hygienic filling machine platform features a unique modular design for exceptional flexibility in installation, operation and maintenance.

Fast, flexible and hygenic

The E-PS120A H provides state-of-the-art aseptic technology for standard cross section, filling 500 ml to 1000 ml. It can even run boards with and without an aluminum barrier. With its flexible speed set-up, the machine can run up to 12.000 packs per hour.

The machine also comes with an integrated control unit with easy access to reports, trends and other events, as well as expert support. The compact, yet easily accessible filling chamber offers fully automated cleaning and 35% H2O2 sterilization without the need for manual intervention.

Key features of E-PS120A

Blank feeding

Requires minimum manpower, thanks to:

- Semi-automatic blank feeding

- One control loading station

- Storage of 4.000 blanks in total

- 20-minute buffer capacity within magazine

Blank wheel

- Space-saving, as no external cap applicator is needed

- More accurate cap application with an internal cap applicator

- Automatic discharge of capless blanks

- Improved hygienic performance, cap-welding with ultrasonic energy and de-duster to remove dust (PE, paper fibers, particles)

Bottom mandrel

More robust bottom seal and optimized energy consumption thanks to the improved bottom folding and shorter sealing time.

Chain unit

- Top double Folding ensures equal folding characteristics

- Pocket design for reliable carton transport

Aseptic chamber

Small Aseptic chamber guarantees:

- fully aseptic performance with well proven H2O2 35% vapor sterilization system

- very accurate filling due to advanced filling system

- controlled sealing properties, less space, improved energy consumption due to inductive top sealing

- less manpower required due to easy, automatic and effective cleaning of aseptic chamber (incl. internal foam cleaning system)

Out-feed conveyor

Flexibly adjustable to customers’ needs.

- Upright carton transport

- Ejection of wrongly-filled cartons

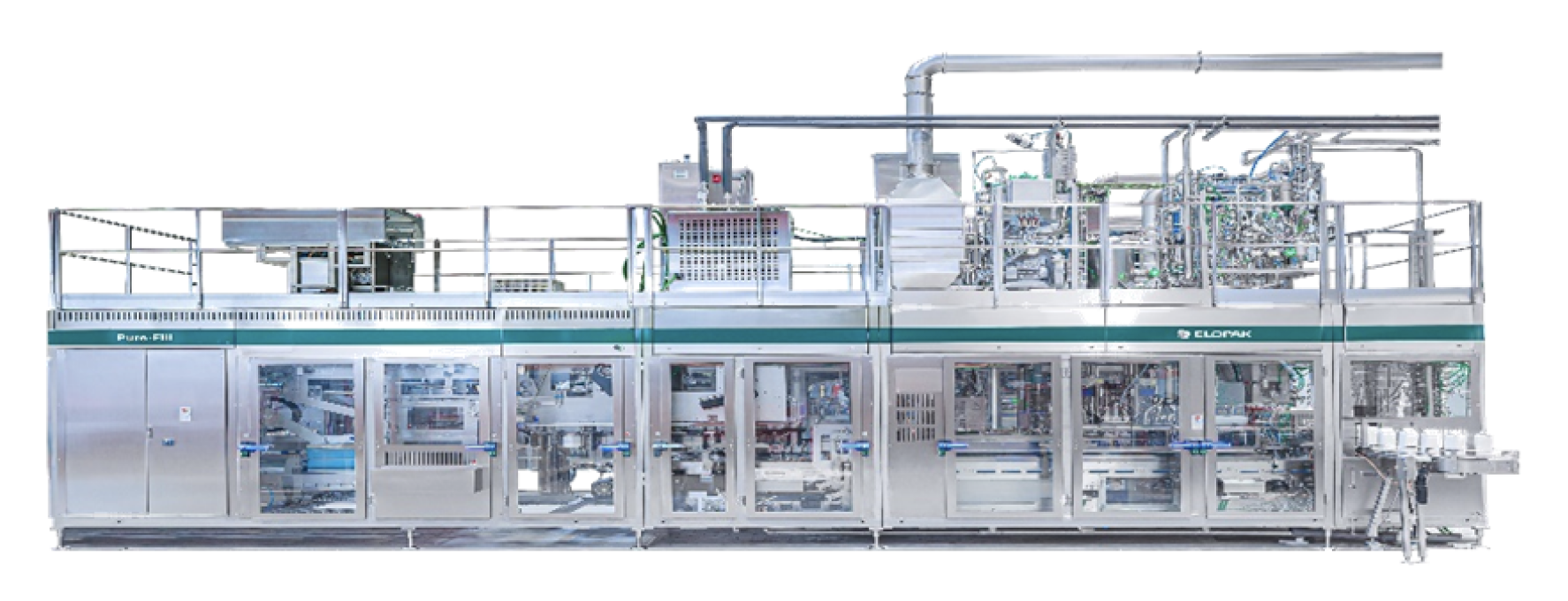

Designed to ensure maximum operational value

Our Pure-Fill system ensures flexibility and operational excellence for family size products ranging from 1500 ml to 2000 ml with a cross section of 91x91mm. With an output of 6000 packs per hour, this machine is ready to support your future needs.

The machine comes with a blank-fed system with a buffer of 20 minutes without manual interference to ensure efficient production, and the integrated control unit offers easy access to reports, trends and events and expert support. With a fully automated filling chamber, the cleaning and sterilization process is performed without the need for any manual intervention.

Key features of Pure-Fill

Cap applicator

Integrated cap applicator with ultrasonic application.

Safe and hygienic

The compact, yet easily accessible filling chamber includes fully automatic cleaning and 35% H2O2 sterilization without manual intervention.

Precision

Double-index highly accurate 1-step filling (< +/- 2 gr) on 4 lines controlled by servo drive to reduce foaming and splashing.