The next generation filling equipment

The S-PSF140UCe is a filling machine that enables optimal shelf life for chilled distribution of your products, ensuring that the food is kept safe and fresh until it reaches the consumer.

The new S-PSF140UCe is designed to meet the highest quality and hygiene standards in the market, and made to be compatible with all our fresh Pure-Pak®cartons. It’s manufactured with high precision to ensure efficient switches between products to reduce food waste and increase production capacity. With state of the art automated cleaning and sterilization processes it ensures safety and ease of use for the operators.

Exceptional hygiene level

A new innovative HEPA air management system provides a unidirectional airflow inside the machine UC-zone. This protects the open carton after filling and enables the longer shelf life of your product.

The number of moving parts in the wet zone have been reduced, which is also reducing the complexity and enables automatic cleaning and sterilization. The CIP/SIP processes are quicker and fully automatic.

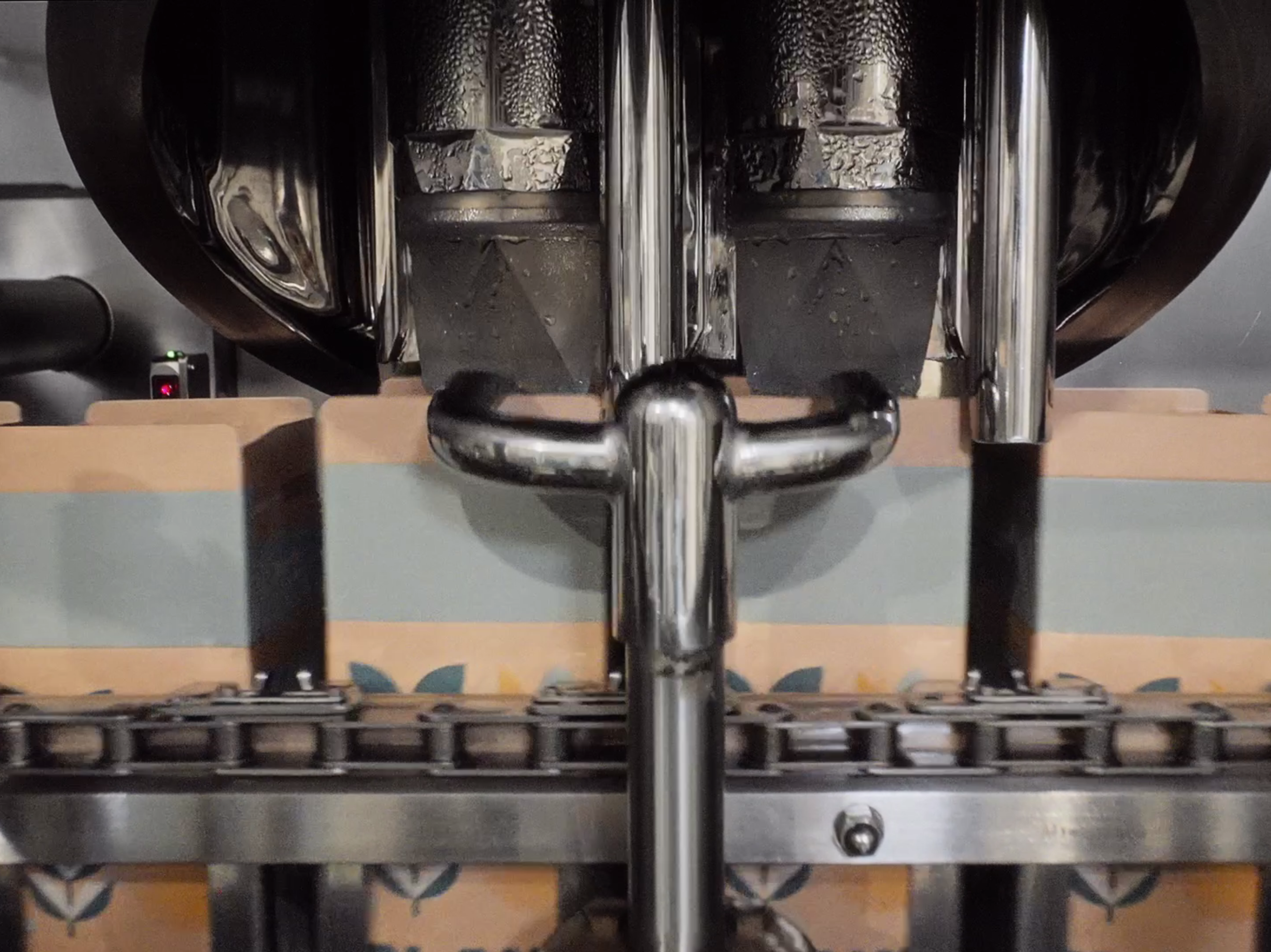

Reliable filling and sealing

The machine is designed to optimize hygiene performance and avoid human errors in a complete closed and fully automated system. The state of the are filling machine is made of robust stainless steel parts according to highest quality standard.

The dual step heating minimizes stress on the polymers and creates the ideal foundation for optimal carton integrity on any chosen board and polymer structure.

Highly flexible in operation

By choosing a dual line, it enables a very high flexibility in operation, allowing you to run different products, cartons or opening solutions on each line at the same time.

You can for instance fill skimmed milk on a Pure-Pak Classic carton with easy opening on one line, and Pure-Pak Sense with whole milk and Pure-TwistFlip on the other line.

Compatible product applications

The machine is compatible with a wide range of chilled product applications. Both high and low viscous products, such as dairy, plant-based, juice, nectars, soft drinks and non-carbonated water can be filled on this machine. This also includes products with particles.

Size and capacity offering

14 000

Dual line capacity pr hour

7 000

Single line capacity pr hour

70×70

Standard cross section

Reducing food waste

The machine is built with high precision, ensuring efficient switches between products which is reducing waste during the filling process.

The exceptional hygiene level of the machine, ensures longer shelf life of your products, which allows more time for distribution and consumption of your products, and ultimately reducing food waste.

Improved safety for operators and service engineers

The machine has a clean design which secures easy access for operators and service engineers during maintenance and service. Hands free cleaning also protects operators from chemicals.

Our decentralized structure of service engineers offering lifetime support ensures customers will have a seamless operation, with focus on high production efficiency, food safety and predictability of costs.

Read more about our technical services.